With this programme, the Fritz and Trude Fortmann Foundation supports basic research projects on building culture and materials.

Salt

Interim report 2023

Technical University of Munich

Gypsum-salt test specimen \ © Image: Technical University of Munich

Gypsum-salt test specimen \ © Image: Technical University of MunichEvery year, 6806 million tonnes of salt are produced as waste in desalination plants and potash production worldwide. The aim of the research project is to utilise the waste product salt as a raw material for building materials. The research is intended to show how the use of salt in combination with various binders, support structures (reinforcements), additives, manufacturing processes and surface treatments affects relevant building material properties (in particular strength and rigidity) and human health (mineral enrichment of the air we breathe due to salty building material surfaces). The aim of the project is to create a basis for the use of salt as a building material for wall and cladding elements in areas with low relative humidity.

The first phase of the research project in 2023 was dedicated in particular to the development of suitable binder/salt combinations and the strength testing of test specimens made from them. As part of the project, it was first determined which salts (chem. composition) occur in desalination plants and potash production. These salts were then simulated in the laboratory and used for further material tests. Other starting materials selected for the salt-containing mixtures without reinforcement and additives were cement (CEM II/A-LL 42.5 R), sand (CEN standard sand according to DIN EN 196), gypsum (CaSO4 - 2 H2O) and clay (clay plaster with straw). During the experiments, it was found that some of the water required to produce the mix escaped much more slowly from the saline binder materials than from the reference material. The reason for this is the reduced physical and chemical water-binding capacity of the salt compared to cement as a binder. Therefore, newly produced materials were stored in a climate chamber at only 50 % relative humidity and 23 °C to accelerate the drying of the samples.

Four different mortar compositions with the following binder/salt ratios were prepared for the test: 100/0, 75/25, 50/50 and 25/75 (M.-%/M.-% in each case). Each mortar composition was mixed with different amounts of distilled water. The mixtures of cement, as binder, and salt exhibited the best processing properties (consistency) of the fresh mortar as well as the highest strengths. This is essential for later use in the production of wall panels. Cement was therefore selected as the binding agent for further processing in this research project. The other material combinations (gypsum-salt, clay-salt) showed only insufficient mechanical properties or had not yet solidified even after 2 months of storage at 60 % relative humidity and 20 °C.

Previous investigations in the project showed that increasing salt content in sustainable concrete increases its density but reduces its compressive strength. To improve the strength properties even with high salt contents, the effect of different hardening additives (Na-alginate and maltodextrin) and the use of support structures (reinforcement with glass fibres, polyvinyl alcohol fibres and jute mats) were investigated. Initial results show that the use of additives in particular has enormous potential for improvement.

The crystallisation of salt in cement-salt material composites strongly depends on the surface geometry and the storage conditions. The addition of salt influences the surface structure and crystallisation begins with nucleation at a certain temperature and humidity. In order to determine the optimum ratio for salt-based sustainable concretes, the influences of different storage conditions and surface geometries on crystal formation have been and are currently being systematically investigated.

Project location: Technical University of Munich, School of Engineering and Design, Chair of Materials and Materials Testing in Civil Engineering, Prof. Dr,.-Ing. Christoph Gehlen, Deputy Head of Institute: Dr, Thomas Kränkel, Franz-Langinger-Straße 10, 81245 Munich

Research post-doc position and project management: Dr. Vesna Pungerčar

Project duration: 2023-2026

Coralline red algae

Interim report 2024

Technical University of Munich

AlgenBauSchutz (ABS) Technical University of Munich

AlgenBauSchutz (ABS) Technical University of MunichBasic studies on coralline red algae as a living performance additive for self-healing binder mixtures

Decarbonization of the construction sector is a top priority for achieving the 1.5°C target set by the World Climate Report to limit global warming. One promising approach involves extending the lifetime of buildings by using living binder mixtures. Here, certain microorganisms, such as specific bacteria and fungi, capture and convert atmospheric CO2 into limestone (calcium carbonate). Hence, age-related cracks can be sealed via metabolically-induced formation/precipitation: CO2 → CaCO3. The high potential of these approaches for autonomous crack sealing, as well as carbon capture, is hindered by several limitations. The dependence of these heterotrophic microorganisms on nutrient availability (encapsulated sugar, nitrogen sources) - crucial for sustaining biomass production and limestone formation – limits the use of this technology to the sealing of small cracks.

The ABS project introduces a novel approach by utilizing calcifying (coralline) red algae, in particular Lithophyllum coralloides. These photosynthetic microorganisms can form cementitious biomass without the need for external nutrient supply or encapsulation. Without this limitation, these marine microorganisms thus have the potential to seal large cracks. Furthermore, spore (the dormant form of this algae) germination and subsequently calcium skeleton build-up could be triggered by crack formation i.e. moisture /humidity and could be promoted or controlled by light input. This innovative approach facilitates processing by bypassing nutrient encapsulation stage, and reduces costs as the calcified spores can be directly incorporated into mineral binders. This strategy is a gateway towards direct carbon capture and long-term storage throughout the lifetime of a building, promoting long-term sustainability and innovation. The aim of the research project is to explore the use of these algae as a living performance additive for self-healing binder mixtures.

L. coralloides have not been fully characterized physiologically, genetically, or biochemically. Environmental samples have been collected and stored at the culture collection of Werner Siemens-Chair for Synthetic Biotechnology. ABS team focused on lab scale cultivation. Temperatures (25 °C, 18 °C, and 7 ° C), light exposure (daylight, blue light, limited red light), antibiotics, anchoring (PVC), as well as the use of a wavemaker were evaluated. In parallel, ABS prioritizes establishing a comprehensive systems biology knowledge base. In our workflow, we adopt a multi-omics approach that integrates genomics, transcriptomics, proteomics and metabolomics. These synergistic techniques could elucidate the fundamental molecular triggers and regulatory controls that drives the calcification process (CO2 → CaCO3) in red coralline algae. Considering the highly mineralized nature of the sample, method optimization of DNA, RNA and proteins extraction is necessary. A demineralization step was incorporated to liquify the calcium skeleton in order to accesses these macromolecules. To that end, a strong acid, HCl, and EDTA, a chelating agent, were evaluated. Other optimizations, including evaluating a number of buffer systems and additives were also performed. Sequencing via state-of-the-art techniques is underway, followed by bioinformatics and data mining.

Another collecting expedition is planned for scaled-up cultivation. Finally, L. coralloides biomass in mineral binder mixtures will be evaluated in collaboration with Prof. Johann Plank, Chair for Construction Chemistry at TUM. The team developed a standardized method for generating reproducible cracks in cement test specimens. These initial tests are crucial in establishing evaluation methods for future visual measurement and documentation of crack reduction.

Project location: Technical University of Munich, School of Natural Sciences, Werner Siemens-Chair for Synthetic Biotechnology, Prof. Dr. Thomas Brück, Vice Dean Research and Innovation, Director of TUM AlgaeTech Center and member of the German National Bioeconomy Council (BÖR), Lichtenbergstrasse 4, 85748 Garching, Germany. Project management: Dr. Dania Awad. Team: Dr. Oyewole Taye Salami, (Chemical Engineering, postdoc) and Weng Yue (Biochemistry, PhD candidate), Jana Holweck (Engineering, M.Sc. thesis), Schmidt-Boelcke and Simon Koppold (B.Sc. internship and thesis).

Project duration: 2023– 2025

Calls for proposals

The foundation has been organising calls for proposals with changing thematic focuses at regular intervals since 2016.

Call for Entries 2025-2026: Monomaterial

A principal characteristic of buildings constructed using monomaterial construction methods is the fact that their support structure and outer skin are made of the same material.

This was not an uncommon practice before building materials became industrially produced, before the large-scale production of steel and concrete and the application of chemistry in buildings and construction took off, and the question arises as to whether and how this basic concept might be meaningfully developed further with regard to traditional as well as newly invented advanced materials.

The monomaterial construction method was put aside when a large supply of pre-produced materials became available that were quick and easy to process and also functionally specialized. By the 1960s at the latest, walls composed of several layers were being built. The increased demand for quality thermal insulation since the 1970s has further contributed to this development.

It is questionable whether this construction method, currently in common use, is futureproof in terms of scarce resources and CO2 footprint. In addition to the vulnerability of heterogeneous building constructions and the constraints on aesthetic possibilities imposed by their standardization, it is the criteria for sustainable buildings that impel us to look for alternatives: these criteria include using ecological materials that are non-hazardous,

constructing buildings that are easy to repair and re-purpose, as well as whose materials can also be reused when a building reaches the end of a particular use and reuse.

With this call for applications, the Fritz and Trude Fortmann Foundation is seeking to promote the subject of monomaterials in architecture and building culture.

Please send us outlines of your ideas, not more than two pages long, by March 31, 2025. Collaborations between engineering and architecture firms are welcome, as are creative contributions from the fields of architecture, design, and art as well as theoretical or historical research projects. The outlines of your ideas must be submitted together with the application form (available at www.fortmann-stiftung.de).

Two research projects that propose new approaches to the development of monomaterial construction can be supported over two years with a contribution of up to EUR 300,000 each. On June 2, 2025 the Foundation will organize a workshop on this subject in Berlin. Invitations to selected authors will be sent out in May 2025.

The call for Entries process takes place every two years. The Foundation's Board of Trustees selects the projects. Legal recourse is excluded.

Growth of A. fischeri on various solids to optimise stability/longevity \ © Image: BioLumCity: Alberto T. Estévez, Jae-Seong Yang

Growth of A. fischeri on various solids to optimise stability/longevity \ © Image: BioLumCity: Alberto T. Estévez, Jae-Seong YangLuminous marine animals and insects, luminescent fungi, algae and bacteria are fascinating. They display a bright, mild light in blue-green hues, which is also particularly appealing because it glows independently of visible energy sources. Since it became possible to produce transgenic organisms in the 1990s, bioluminescence has become an important subject of research not only in biotechnology but also in the visual arts. In contrast to fluorescence, bioluminescence does not require any external light sources. The light is actively produced by internal chemical reactions in the organism.

There are also experimental models for bioluminescence in design and architecture. New research into the intensification and amplification of light has expanded the options available for the development of integration into design processes. One of the goals is to generate a clean, sustainable and affordable plant-based alternative for light sources and to reduce the globally lamented ‘light pollution’ in urbanised landscapes with softer illumination. In the 2023-25 funding period, the Fortmann Foundation is supporting two research groups in Barcelona and Osnabrück that are looking for new perspectives in regard to bioluminescence.

A workshop was held as part of the bioluminescence funding programme.

BioLumCity Research Project

ABSTRACT - 1st Interim Report -

Growth of A.fischeri on different solid media to optimize its durability \ © Image: BioLumCity: Alberto T. Estévez, Jae-Seong Yang

Growth of A.fischeri on different solid media to optimize its durability \ © Image: BioLumCity: Alberto T. Estévez, Jae-Seong YangThe BiolumCity Project wants to offer an advanced way of real bioluminescence application in architecture and urban design. First, attending to the already existing natural sources of bioluminescence, choosing among the most suitable living organism for the case, bioluminescent bacteria, enough effective in not illuminated interiors. But, given the limitations of its relatively weak luminescence, and also since the current urban artificial light does not allow bioluminescence to be perceived, it is proposed also to create a genetic modification in microalgae that allows greater light efficiency. While on the other hand, genetically modified organism and those that are not, both for a greater lighting effect, will be supported on panels of different scales, from objects scale, lamps and furniture, to showcases, storefronts, window displays and facades scale. Digitally manufactured panels in a very special way, with transparent material and bio-learned algorithms, as we are used to design, that assure the functional efficiency and the perception of beauty. So, using digital design development, the panels -in every scale -emerge with the values of harmony, unity, continuity, organicity, diversity, dynamic, complexity, fractality: the values of an "objective beauty" that every living being has in nature: values to be seen also by day, when bioluminescence can't be perceived. To this end, between January and June 2024, work was carried out on the following objectives.

From one side, the project aims to develop bio-receptive tiles and bioluminescent systems for architectural and urban applications, focusing on the bioluminescent bacterium Aliivibrio fischeri. Objective 1 designs bio-receptive tiles using AI-based generative models, 3D printed with translucent PLA, to support bacterial chemotaxis and biofilm formation. Objective 2 creates bio lamps as vertical urban bioreactors, employing Voronoi structures for efficiency and strength. Objective 3 optimizes the cultivation of A. fischeri, establishing ideal growth conditions and media compositions. Objective 4 focuses on molecular techniques for transforming chloroplasts with the lux operon. Objective 5 establishes "in vitro" culture lines for transplastomic plants to enhance urban landscapes.

And from the other side, the project aims to establish bioluminescent systems in microalgae and create a co-culture system with bioluminescent E. coli and yeast. Objective 1 focuses on designing Chlamydomonas-specific luciferases by cloning genes from luminescent fungi and optimizing their expression in Chlamydomonas. Successful transformation and selection of bioluminescent clones were achieved. Objective 2 involves setting up bioluminescent E. coli using an enhanced lux operon and optimizing conditions for bioluminescent yeast using a commercial cassette. Optimal growth and luminescence conditions for yeast were determined. This work lays the groundwork for future biotechnological applications of bioluminescent systems in these organisms.

Alberto T. Estévez Group Leader iBAG-UIC

Jae-Seong Yang Group Leader CRA

Barcelona, January-June 2024

Funding period 2020-2022: Material in abundance

With this call for proposals, the foundation supports concepts, research and designs that focus on materials that are abundantly available but have so far been limited in their use. In times of increasingly scarce raw materials, it is not only a question of minimising consumption, but also of tapping into new or unused resources. Materials such as - CO2 (‘carbon storage’) - rubble concrete from dismantling and demolition (concrete recycling) - algae - salt - gypsum - grasshoppers - plastic are conceivable.

Many of these materials are not yet considered resources, but are treated as waste and disposed of in a mostly environmentally harmful way.

How can these substances be processed and turned into new materials? What functions could they fulfil? Which of their properties could be utilised? What reinterpretations are necessary in order to no longer regard such materials as waste, but as raw materials?

Biomatter Building Parts

Investigation of the composite of chitosan biopolymer films and willow filament for sustainable components

University of Kassel

_674x1348.jpg?t=1732103329) Chitosan samples \ © Image: EDEK, University of Kassel

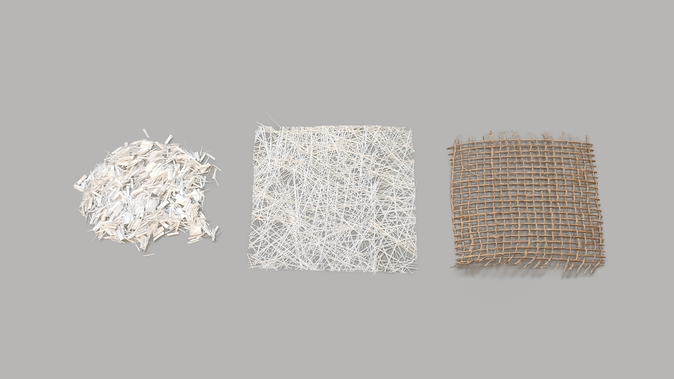

Chitosan samples \ © Image: EDEK, University of KasselIn the Biomatter Building Parts project, investigations were carried out into the production and moulding behaviour of chitosan-based biopolymer films reinforced with willow filament. Chitosan can be produced from chitin, which is a waste product from the processing of shellfish and industrial insect farming. This flow of materials gives rise to a need for research into new techniques for the further utilisation and possible applications of chitosans. The investigations carried out were intended to provide a systematic basis for the development of architectural components. The aim of the project was to create a new sustainable composite material that has the potential to replace petroleum-based composites.

Biomatter Building Parts initially focussed on the questions of which chitosans (crustacean, insect or fungal chitosans) are suitable for the production of films and which process can be used to produce the material composite with willow filaments. Furthermore, the structural properties of the resulting films were to be characterised.

Chitosans from crab shells and fungi, which are particularly suitable for the project due to their material properties, were investigated in more detail. The extrudability of chitosan hydrogels and a material composite by applying willow filaments were also investigated. Special robot moulds were developed for this purpose.

The tensile strength of both pure chitosan films and chitosan films reinforced with willow filaments was determined by means of structural tests carried out in collaboration with the Department of Separating and Joining Manufacturing Processes.

The design possibilities were then investigated by applying willow filament to the films in various geometries using robot-assisted application technology, similar to a 3D printing process. The deformation process that occurs when the membranes dry was analysed and controlled by adjusting the wood filament layout.

The project developed robot-manufactured material composites made of chitosans with willow filaments that are both aesthetically pleasing and have a very high tensile strength. This created a systematic basis for the design, automated production and application of large-scale architectural components. Further research is required to transfer the research results to date to a larger scale and to functionalise the materials for architectural requirements.

Project location: University of Kassel, Universitätsplatz 9, 34109 Kassel, Research Centre for Experimental and Digital Design and Construction, Prof. Philipp Eversmann

Project duration: 2021-2022

_674x506.jpg?t=1732103439)

On the road to synthesised wood

Tailor-made textile profile preforms made of flax fibres and bio-resin for the design of biocomposite structures

University of Stuttgart

Demonstrator with load-bearing biocomposite profiles \ © Image: ITKE University of Stuttgart

Demonstrator with load-bearing biocomposite profiles \ © Image: ITKE University of StuttgartThis project investigates how the production of customised profiles from flax fabrics laminated with a bio-based matrix could offer new possibilities and perspectives for increased in architecture.

Until now, the use of natural fibres in architecture has mainly been associated with primitive vernacular architecture. But the new category of biocomposites - natural fibre-reinforced polymers (such as those used in this project) - shows them from a completely new perspective, still unknown to ordinary end users and sometimes even to architects and engineers.

Once natural fibre textiles (in this case made from flax) are processed into durable biocomposite components, they resemble synthetic wood due to their fibrous nature. They could be used for any function in architecture, potentially replacing wood elements in various applications ranging from interior partitions to load-bearing structural elements such as beams, columns and entire shell systems.

Apart from this, there are also scenarios in which the use of biocomposite elements could be more sustainable and economical than wood. This applies in particular to all constructions based on freely moulded wooden beams. The production of such beams from wood is relatively complicated and leads to material losses. With automated preforming of natural fibre textiles, on the other hand, the production of freely shaped, curved or twisted biocomposite profiles would require the same amount of work as straight profiles.

Consequently, implementing even minimal customisation options into the automated preforming process can radically increase the design possibilities within the standard biocomposite profile production process. In addition, the manufacturing process remains additive and material losses are reduced.

How can synthetic wood made from natural fibres shape the architectural design of the future?

The project provides an answer to these questions by presenting the design and manufacturing process that led to the realisation of a structural demonstrator with load-bearing biocomposite profiles. The demonstrator serves as a proof-of-concept for the proposed design framework based on the concept of automated production of textile preforms from natural fibres for customised biocomposite profiles.

Project location:

University of Stuttgart, Institute of Structures and Conceptual Design (ITKE)

Department of Bio-based Materials and Material Cycles in Architecture (BioMat)

Keplerstrasse 11, 70174 Stuttgart

Project duration: 04.2021 - 03.2022

Project leader, seminar tutor: M.Sc. Piotr Baszyński

Seminar Examiner: Jun.-Prof. Dr.-Ing. M.Eng. Arch. Hanaa Dahy

Student Assistants: Vanessa Costalonga Martins, Mykola Tsyharin, David Schadwill

Seminar Students: Ann-Marie Klar, Elena Grimbacher, Mathilde Josse, Mykola Tsyharin, David Schadwill, Alina Engel, Anna Prokhorenko, Alina Mykhaylova, Laura Andrea Hurtado, Irene Calero Pages, Muhammed Ali Vural

Technical support: Michael Schneider

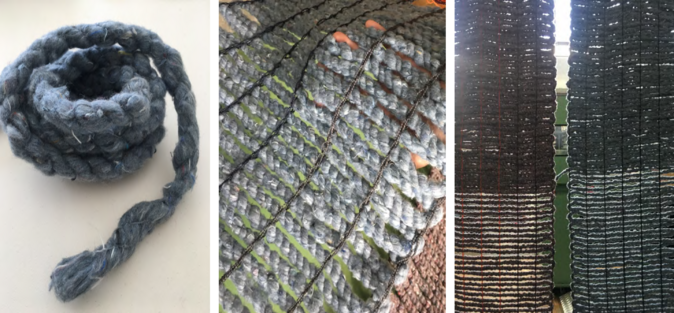

Cotton Dust - new textile surfaces

Utilisation and processing of waste products from the textile industry

University of Stuttgart

Cotton Dust - new textile surfaces \ © Image: Svenja Boissel and Lil Petersen

Cotton Dust - new textile surfaces \ © Image: Svenja Boissel and Lil PetersenThe research project Cotton Dust - new textile Surfaces deals with the use and processing of cotton lint, which is produced in large quantities every day in the textile industry as dust-like waste products. Most of the lint is produced in terry weaving mills. Two to five tonnes per year in just one weaving mill. This lint is regarded as the end point of the textile production chain, without any ideas for sustainable recycling. We have found a new starting point for the design of innovative textile surfaces in this supposed waste.

As a rule, leftovers from the textile industry are - if at all - processed into downcycled products. We strive for the opposite: Our focus is upcycling! As designers, we reintroduce cotton lint into the textile production cycle and thus help to shape the entire textile value chain.

Cotton Dust has primarily focussed on the question of how new surfaces can be created from both mono-materials and combinations of fabrics, taking into account specific material properties. Our starting point and focus has always been textile interior design.

We used the machines of the Saxon Textile Research Institute in Chemnitz for the implementation.

The lint is sieved onto a carrier material by a machine that normally produces conventional thermo-bonded nonwovens. The resulting surfaces are then moulded into stable surfaces using a hydroentanglement machine. This machine has been specially developed for bonding short fibres. Compared to other types of bonding, AquaJet hydroentanglement does not require any binding agents or fusible fibres. The pressure of the water jets is sufficient to bond the fibres together. Continuous high-pressure water jets hit the loose material, which is moved on a screen under the water bars. Suction fans extract the water contained in the fibres. This production process guarantees tensile strength and gives the material its textile feel.

An important part of our research was to find out which carrier material bonds best with the cotton dust and is therefore the ideal substrate. When selecting the materials, we opted exclusively for cellulosic materials such as jute and cotton due to their subsequent recyclability. We also tested various fabric strengths. In addition to a permanent bond between dust and fabric, we also wanted to find out whether it is possible to bond the dust without a carrier material. For technical reasons, however, we also had to work with a synthetic spunbonded nonwoven as a carrier material for these tests, which can be removed again after solidification.

Another important aspect of the research process was the design possibilities. We saw the greatest design potential in the colours of the cotton lint. In order to use these in pure colours, we sorted the lint directly during the creation process. The research project shows that the seemingly impossible is possible: producing a textile, flexible and stable surface from dust. Our results can be used indoors as sound-absorbing wall panels. As proof of this, we carried out tests in the acoustics laboratory at the TU Berlin. The tests carried out show that the textiles developed can withstand conventional acoustic curtains. We now see the next step in direct product development. The task now is to find companies to co-operate with and develop further.

Svenja Boissel and Lil Petersen

Funding period 2018-2019:

Sense for material - material for the senses

Funding was provided for projects and research projects that investigated the interaction between the use of materials and sensory perception.

In contrast, digitalisation and virtualisation are increasing the fascination of objectivity, haptics and sensory perception of the designed environment, which goes far beyond visual communication through image

media. So-called ‘material libraries’ serve the desire to touch when testing materials. When using materials, many designers aim for a direct stimulus character of the objects; conversely, new materials react to environmental influences and user behaviour (colour, heat, pressure). The use of responsive materials in public spaces (whispering asphalt, roaring concrete, relief floors) is said to have a behaviour-directing effect. In turn, there are materials whose surfaces suggest other materials without possessing the corresponding properties, a kind of 'fake materials. The properties of materials can be particularly emphasised or manipulated in machining processes in order to enable special sensory experiences.

A workshop was held as part of the funding programme on the sensory aspects of material promotion.

Building with salt

The use of salt as a building material in new material mixtures.

A research project at the Chair of Building Construction and Building Materials Science at the Technical University of Munich under the direction of Prof. Dipl.-Ing. Florian Musso.

Basis

The starting point for the research project is the consideration that, according to UNESCO, almost half of the world's population live in areas where there is not enough water for at least one month a year. The water shortage currently affects around 3.6 billion people. One solution to this water shortage is to desalinate seawater. Around 19,000 desalination plants are already in operation around the world, extracting drinking water from seawater and returning the extracted salt to the sea. In the United Arab Emirates alone, this amounts to around 120 million tonnes of salt per year. This increased salt content in the sea threatens fish stocks, corals and aquatic plants.

In order to counteract this problem, the possibilities of using salt as a new building material for architectural applications are to be investigated. Sea salt is porous at room temperature, dissolves in water and stores three times more thermal energy than water. As it is not possible to use the material directly, a combination with other binding agents should influence the properties of the building material.

The resulting salt material composite offers new insights in the perception of the material through smelling, seeing, hearing, tasting and feeling. The utilisation of the available material in combination with bondable materials offers the potential for a pressure-resistant material composite that can take on climate-regulating functions. In this way, salt-based building elements can be created for walls, even though salt is normally considered a substance that is harmful to buildings. The main aim of the research project is to design and plan the exact mixture of such materials.

New possibilities for sensory perception

Salt blocks should not only be the main structural component, but also influence people's sensory perception. Taking this into account, the properties are to be investigated using demonstrators on a 1:1 scale:

- Smell: The influence of salt on the quality of indoor air will be investigated here. Increasing humidity has a negative influence on the perception of odour. In addition, salty air is already used in medicine to treat respiratory diseases. The salt block is intended to improve humidity and the perception of odours.

- Vision: The visual comfort in a room is to be analysed through light reflection, colour and surface structure of the material.

- Hearing: The ability of the new material composite to absorb sound is to be analysed.

- Tasting: The toxicity of the material will be tested and it will be found out whether salt blocks are also suitable for an environment with children.

- Touch: The thermal comfort of the material will be investigated by analysing the surface temperature.

Salt material compounds test specimen - surface (efflorescence) \ © Image: TUM EBB

Salt material compounds test specimen - surface (efflorescence) \ © Image: TUM EBBStructures made of mycelium for the interior

Research and development of a sound-absorbing material made of fungal mycelium and plant fibres.

Jonas Edvard Workshop \ © Image: Jonas Edvard, Kopenhagen

Jonas Edvard Workshop \ © Image: Jonas Edvard, Kopenhagen Research project and artistic installation by Jonas Edvard, industrial designer, Copenhagen

The objective of this project is to research, evaluate and develop the potential of mycelium as a rapidly renewable, regenerative and affordable, carbon-free building material. It aims to promote the acceptance of mycelium as a building material through applications that enable a variety of sensory experiences in indoor spaces.

Mycelium is an excellent material for the production of acoustically absorbent building elements and could offer new possibilities for interior design. A test phase will be followed by an analysis of the appropriate material form for efficient and comprehensive processing in building interiors. Finally, conclusions about potential application sites can be made.

The intention is to continue researching mycelium as a building material and in particular its technical and sensory properties in a multidisciplinary process in order to create clear and emotionally appealing surfaces.

Mycelium is an intelligent material and offers the possibility to act as an adhesive between fibres and, through its ability to ‘grow together’ materials and elements, as a stabiliser of the construction. This process can be manipulated by heat, temperature and pressure to create the desired properties, textures and colours.

Materials such as mycelium can contribute to a healthy working environment, especially in open-plan offices - for example through their ability to absorb sound. Our collaboration aims to explore unexpected approaches in this area through creativity, collaboration and imagination. As office spaces change with the rapid development of new technological systems and communication channels, it is becoming increasingly important to create adaptive spaces and flexible spatial solutions that engage all our senses. The use of mycelium-based materials and products can enhance the haptic and emotional connection between the space and its users.

This project therefore ultimately aims to explore mycelium as a healthier and more sustainable alternative to traditional sound-absorbing materials. It seeks to investigate the sensory properties of materials by overcoming the immediate association of the mycelium fungus with food or mould.

As sustainable material choices become increasingly important for designers, engineers and consumers alike, the associated experience needs to be further designed. The influence of emotions on consumer behaviour can contribute to an increasing interest in more sustainable lifestyles. A positive association and experience can raise awareness of alternative building materials such as Myzelium. In addition, collaboration between designers, engineers and the construction industry can further advance research and drive the development and integration of mycelium into the built environment.

Breathe IN / Breathe OUT - NUATAN.

Exploring scents of future materials.

The project focused on the development of an odour library for organic bioplastics.

Building materials are primarily assessed on the basis of visual and haptic properties, with odour properties taking a back seat. However, odour plays a central role in the emotional acceptance of a material and plays a key role in determining its appeal.

The human brain's ‘odour library’ is largely shaped by experiences in early childhood and every aroma is associated with an emotion. Scents have an immediate and direct effect on the brain, stimulate behaviour and, among other things, facilitate orientation in a room. The Proust effect describes the evocation of memories from the past through a single odour. This phenomenon plays a key role in the recognition and intuitive use of new materials.

The smell of organic bioplastics has hardly been researched; no aromas are associated with the material. The project funded by the Fortmann Foundation focused on the transfer of aromas into a construction material made of bioplastic and the development of an odour library for organic bioplastic. The project was developed in a transdisciplinary collaboration between crafting plastics! studio and OFFICE MMK in close collaboration with material scientists and neuroscientists.

In order to identify, analyse and present the potential of aroma-active bioplastics in a structured way, existing findings on the topic of bioplastics in the circular economy and existing classification methods for evaluating odours were reviewed.

Using the organic bioplastic NUATAN, the question of how bioplastics smell was then investigated. The bioplastic developed by crafting plastics! studio consists of PLA and PHA, is petroleum-free, made exclusively from renewable raw materials and is completely biodegradable. Visually, the material differs significantly from conventional plastics and can be used for the manufacture of value-added products thanks to its unique combination of polymers.

Material tests have shown that the addition of organic material creates odour aromas that make NUATAN olfactorily distinguishable from oil-based plastics. The researched aromas were materialised in an architectural skin. This skin metaphorically stands for the skin as an interface to the world and describes the breathing process in architecture as the processing of natural raw materials into human living space.

Based on the results of the experiments, an odour library was developed and presented at Milan Design Week 2019. Spatial use cases were defined in several design workshops and a material prototype was fabricated. The olfactory experience was presented in a spatial installation at the Vienna Biennale for Change 2021 at the Museum of Applied Arts (MAK) Vienna.

Foam house

Foam as a space-creating material and its sensory properties.

Research project at the Institute of Building Construction, Chair 2, Faculty of Architecture and Urban Planning, University of Stuttgart under the direction of Prof. Martin Ostermann

Foam is a multitude of gaseous bubbles that adhere to each other and are enclosed by solid or liquid walls. Foam has no edges, no solid outlines, no describable form. It is transient, unstable, porous and dissolves. Foam yields to pressure, is light and soft. Its structure is directionless, it is freely mouldable and workable. Touching foam is perceived as unpleasant. It reacts unpredictably, reflects sound in all directions, dampens and insulates.

While conventional building materials such as stone, concrete, painted wood, plaster etc. are almost exclusively cold to the touch, foamed surfaces radiate warmth. The energy comes from the human body and is reflected back to it.

Based on these fundamental differences from conventional building materials and considering the specific properties of foam, the project's goal is to investigate the sensory effects of foam and refine its perception in terms of sensory experience.

The starting material is a bio-based, industrially compostable rigid foam that is currently used in the packaging industry. This new type of rigid foam is cradle-to-cradle (EPEA, 2015) certified and 100% CO2-neutral. It is completely harmless and can be processed like normal rigid foam.

From foaming to heating to cutting, the possibilities of material production and processing are being explored. The aim is to develop modular system parts that can be joined together to form a space-creating structure. Particular attention is paid to the development of details for joining the material that enable a secure connection despite its softness.

Not only the material, but also the three-dimensional processing and surface design promise diverse acoustic, haptic and visual levels of experience.

The resulting solutions should be ‘cradle-to-cradle’, i.e. all connections are detachable to allow the materials to be reused.

Funding period 2016-2017: Cost-effective building materials and construction methods for housing construction

The first call for tenders focussed on concepts and designs for low-cost housing construction, in which the quality of the materials plays a decisive role.The foundation supported projects or research projects that related to the development and production process of cost-effective materials or to the processing or constructional realisation. The following parameters were set as criteria for cost-effective materials:

- Economy and energy efficiency

- Sustainability in production

- Durability and recyclability

- Low processing costs and easy further construction

- the ability of the materials to be integrated into the structural and social context of a building.

A workshop was held as part of the funding programme for cost-effective construction

TXXL – Upscaling Textiles

The research project investigated the potential of the textile process engineering coarse knitting for functional architectural interior elements.

Christiane Sauer, formade 2018/19

As part of the TXXL-Upscaling Textiles research project, the potential of the textile process technology of warp knitting for functional architectural interior elements was tested using material studies and demonstrators. Coarse knitting is a special form of warp knitting technology that can be used to process yarn-like elements with a material thickness of up to 30 mm. Flexible surfaces with a thickness of up to 3 cm and a width of 1 metre can be produced from the roll in free lengths. This means that this textile technology can be used on a scale that corresponds to architectural materials. Until now, coarse warp knitting has mostly been used in technical applications, e.g. for geotextiles in slope stabilisation. The challenge of this project was to develop design approaches that fulfil design requirements in addition to technical properties. In the course of the test series, the focus was particularly on sustainable and cost-effective concepts for room acoustics and room air conditioning and corresponding materials such as recycled fibres or phase change materials (PCM) were examined in this respect. All demonstrators bind the components exclusively through textile construction, which allows the individual elements to be very easily detached and separated into their original materials at the end of their life cycle. This is a major advantage over conventional structural elements in which functional components are firmly integrated, e.g. by means of a binding matrix or lamination.

In the manufacturing process, fibre-like components were first processed into flexible, centimetre-thick ‘yarns’ using a special process for producing strands (Kemafil®) and then bound into surfaces using coarse knitting. The realised examples show a wide range of possibilities for producing functionally effective and flexible semi-finished textile products in a simple way. Curtain-like panels, which can be used in front of windows, walls or hanging freely as room-defining elements, also serve as acoustic or climate control elements. The result is lightweight, flexible modules for interiors that can be adapted ‘off the roll’ to any desired length and geometry, are easy to transport, easy to stow, cost-effective and simple to install. In particular, sustainable material concepts were investigated, such as the recycling of used textiles (tear fibres), felt cuttings from the textile industry or renewable raw materials such as hemp residues from the insulation industry. For climate-regulating functionalisation, paraffin-based phase change material (PCM) was used, which buffers temperature peaks in the interior and thus protects against overheating or cooling through large glass surfaces, for example. For this purpose, functionalised, non-textile elements such as tubes or rods were incorporated into the material in the weft direction during the knitting process.

Room acoustics: Plant fibres or used textiles are already widely used for sound insulation purposes, but not as flexible curtain elements. As part of the research work, new design approaches were developed for the processing of aesthetically inferior used textiles, textile industrial waste or insulating materials. The fibre materials are used unmodified as supplied. Their insulating properties due to the fibre structure are retained and are used directly for acoustic absorption. The result is visually and haptically appealing surfaces that do not hide their origin but, on the contrary, utilise it as an individual design feature. The textile processing of the resulting demonstrators transfers recycled or residual materials into a high-quality design context. The result is an upcycling concept that enhances the original material by transferring it to a new area of application. The knitted panels, which are easy to transport and install, are particularly suitable for retrofitting existing rooms. In addition, textile surfaces have the advantage that they can be individually adapted to different usage scenarios or acoustic requirements as movable elements and can also be used as free-hanging elements for spatial organisation. The textiles have been designed in such a way that they fit equally well in a home, office or school environment. In working and learning environments, good acoustics are a decisive factor for well-being,attentiveness and user comfort. The results show cost-effective and resource-saving, sustainable solutions for this.

Indoor climate: As window areas and large glass surfaces in particular cause additional heat to enter the building, climate-buffering curtains in the interior can also be suitable as an easily retrofitted air conditioning measure in addition to efficient external sun protection. As part of TXXL, climatically effective phase change materials (PCM) were incorporated as rods or tubes with textile technology. The resulting panel curtains can be used in front of windows or hanging freely in the room as room dividers. The PCM elements store heat during the day and release it back into the environment with a time delay when it cools down at night. A mass integration of PCM material in tubes or hoses with a diameter of 1-2 cm has the advantage that relevant quantities of the active material can be integrated. Compared to existing PCM-coated fibres, from which textiles can also be made, a significant increase in effectiveness can be expected due to the greater mass of the active material introduced. Depending on the climatic requirements and room size, the arrangement and density of the rods or tubes can be adapted - while at the same time being transparent and visually connected to the outside. The visible phase transition from solid to liquid is also a fascinating visual spectacle. Retrofitting in existing buildings is very straightforward. The technical elements can be adapted to changes in use or individual preferences and, like panelled curtains, can simply be pushed to one side or easily removed or moved. Air conditioning technology is no longer hidden, but becomes an active and customisable element in the room. This concept of ‘smart material’ air conditioning textiles could reduce the energy consumption of conventional air conditioning systems or possibly replace them altogether. Technical measurements of the demonstrators will provide further application-orientated findings as part of future studies.

Sound-absorbing acoustic curtains, yarn made from recycled denim fibres \ © Image: Christiane Sauer, formade

Sound-absorbing acoustic curtains, yarn made from recycled denim fibres \ © Image: Christiane Sauer, formade Sound-absorbing acoustic surface, insulating filler: hemp fibre sections \ © Image: Christiane Sauer, formade

Sound-absorbing acoustic surface, insulating filler: hemp fibre sections \ © Image: Christiane Sauer, formade Climate-active panel curtain with phase change material (PCM) in the yarn strand \ © Image: Christiane Sauer, formade

Climate-active panel curtain with phase change material (PCM) in the yarn strand \ © Image: Christiane Sauer, formade Climate-active panel curtain with phase change (PCM) elements, visible phase change from solid to liquid in the material \ © Image: Christiane Sauer, formade

Climate-active panel curtain with phase change (PCM) elements, visible phase change from solid to liquid in the material \ © Image: Christiane Sauer, formadeCoarse knitted fabrics as functional surfaces

NAVAPA - Sustainable composite components made from paper materials

Honeycomb panels made from recycled paper from the packaging industry are to be used in architecture.

Components made from honeycomb panels \ © Image: Stephan Schütz / Bauhaus-Universität Weimar

Components made from honeycomb panels \ © Image: Stephan Schütz / Bauhaus-Universität WeimarThe research project ‘NAVAPA - Sustainable composite components made of paper materials’ by Dr. Stephan Schütz from the Bauhaus-Universität Weimar has been selected for funding by the Fritz and Trude Fortmann Foundation as part of the first call for proposals 2016/17 ‘Cost-effective building materials and construction methods for residential construction’. The aim of the project is to open up new areas of application in architecture for honeycomb panels made from recycled paper, which have primarily been used in the packaging industry to date. The aim is to use folded honeycomb panels to develop and analyse ecologically sustainable, material-saving and energy-efficient wall elements as a cost-effective and recyclable alternative to conventional metal stud walls for interior design.

The project is based on geometric studies already carried out on the foldability of honeycomb panels as well as tests with folded column and beam geometries and a realised experimental building. Building on this, holistic wall elements for the interior with a core structure of folded honeycomb panels and panelling with, for example, wooden panels or plasterboard are now to be developed. The aim is to combine the supporting structure and panelling in one component and to develop an assembly system with easy-to-handle connection details. The advantages compared to conventional metal stud walls would be a high degree of prefabrication and the resulting significant reduction in the amount of labour required for the interior work, as well as a positive ecological balance due to the material-saving structure and the use of recycled paper. Overall, the costs are expected to be low in terms of the specifications, while the quality of workmanship is expected to be high.

The funding provided by the Fritz and Tride Fortmann Foundation will be used for material procurement, test series and the construction of an experimental building at the University of Weimar.

Research project ‘NAVAPA - Sustainable composite components made of paper materials’

Bauhaus University Weimar

Chair of Design and Structural Engineering, Prof. Rainer Gumpp / Dr. Stephan Schütz

Implementation period: 2017-2018

Roof superstructures

Potentials of different materials and construction methods for the creation of inner-city living space through roof superstructures

Research project 2017-2018

Konrad Freymann, Jakob Grave Simon Madlener, Berlin.

Funded by the Fortmann Foundation as part of the 2016 call for proposals ‘Cost-effective building materials and construction methods for residential construction.’

The project authors are graduates of the Civil Engineering, Industrial Engineering and Architecture departments at TU Berlin. They investigated the potential of different materials and construction methods for the creation of inner-city living space through roof structures. In conjunction with innovative digital planning and production processes, the aim was to find more cost-effective and therefore more socially acceptable options for this construction task, which is usually characterised by cost-intensive individual solutions.

Following an examination of the urban planning and social aspects of urban redensification through roof superstructures, the structural and material technology aspects were at the centre of the investigation. The specific requirements for materials and construction methods for roof superstructures were determined and compared with the properties of ‘wooden panels’, ‘solid wood’, ‘metal & glass’ and ‘infra-lightweight concrete’. In addition to aspects such as economy, energy efficiency, connectivity and durability, the study also focussed on prefabrication and simple assembly as well as innovative manufacturing techniques such as robot-assisted series production: How can established materials gain in effectiveness through new manufacturing techniques? Which new materials are cost-effective and suitable for roof superstructures?

The most promising material solution was then trialled in a model with large-scale construction details. The aim was not to develop an individual structure, but rather a concept that could be adapted to the surrounding environment and could form the basis for the redensification of cities such as Berlin.

Workshop 2023

Bioluminescence

Bioluminescence is a fascinating phenomenon that describes the incredible ability of certain living organisms to generate light without producing heat.

The ability to produce natural light through chemical interactions of enzymes and molecules is widespread in the animal and plant world. The potential of this mysterious luminosity of living systems exerts a tremendous attraction on many disciplines, such as biochemistry, biotechnology, synthetic biology, architecture and urban planning or bio-design and the visual arts.

In the 2023-25 funding period, the Fritz and Trude Fortmann Foundation is focussing on the potential of bioluminescence and exploring the question of how previously applied and newly developed scientific research findings on bioluminescence can be incorporated into materials research in building culture. Can natural systems capable of bioluminescence become reliable and sustainable light sources in the near future to supplement or even replace conventional forms of lighting? The creation of light sources that work without electricity could permanently change the way we light our world.

There are good reasons to be optimistic, as current research is working both on increasing the efficiency of bioluminescent light and on ways to integrate robust and environmentally friendly living light forms into the design process. Whether the technical application of bioluminescence will develop in a direction that makes it safe (non-toxic) and suitable for mass application remains to be seen.

Replacing electric lighting with organic forms of light can be done on basis of plant nanobionics or on engineered plants (including the incorporation of bioluminescent systems of fungi or bacteria into plants). Both could save energy and help cities and communities worldwide to achieve net-zero emissions or even become climate-positive, i.e. create an environmental benefit by removing additional carbon dioxide from the atmosphere. The figures illustrate that this is also an important field of action in quantitative terms: Artificial lighting, whether indoors or outdoors, is a major component of global electricity consumption. As the global energy mix is still heavily dependent on fossil fuels, artificial lighting is responsible for almost 20 per cent of global carbon emissions - with all its dire consequences for the increasing global warming of the planet.

Attempts to make lighting cheaper and more efficient have been around for a long time. These include highly efficient technologies such as LEDs (Light Emitting Diodes), tiny electronic chips made from special semiconductor compounds. When electricity flows through LEDs, they begin to glow and ‘emit’ light, which is why this process is also known as electroluminescence. However, in recent years - despite the energy-saving benefits of LEDs - it has been scientifically proven that LED lighting is not only harmful to the human eye, but can also contribute significantly to light pollution and pose a growing threat to biodiversity. Ecosystems can tolerate a certain level of human use without negative impacts - a property commonly referred to as resilience - but beyond a certain threshold or tipping point, sudden, radical and sometimes irreversible damage can occur. LED lighting can have a negative impact on our biodiversity as it contains more light in the blue wavelength range, which disrupts the natural day and night rhythms of many species, including species that are important to our food web. The current rate of loss of global biodiversity is estimated to be 100 to 1000 times higher than the (naturally occurring) background extinction rate and is expected to increase further in the coming years. This makes it clear that a system change is also unavoidable in the production of light that integrates these findings, and promotes the development of alternative models.

Exploring the potential of bioluminescence and supporting researchers in this important and promising field of research is the goal that the Fritz and Trude Fortmann Foundation has set itself in 2023 and for the next two years. In the first quarter of 2023, the foundation launched a call for funding and approached the international research community from various scientific disciplines as well as artists who are involved in the study of bioluminescence and its translation into concrete projects and designs. In the multi-stage process, seven international project groups were ultimately invited to Berlin on 14 July 2023 for an intensive one-day exchange.

The venue for the event was the Kantgaragen in Berlin-Charlottenburg as a reference to building culture. An early modernist building that paid tribute to the changing times during its construction in the 1920s with a completely new type of building as a multi-storey car park and automobile service building. Since its rededication in 2022, this extensively renovated building has been available as a conference and event venue and in this case has created an excellent link between research, funding issues, building culture and future orientation.

After a warm welcome by Nicola Fortmann-Drühe, Prof. Dr. Susanne Hauser, Chairperson of the Board of Trustees of the Fritz and Trude Fortmann Foundation, introduced the topic, supported by a keynote speech by Prof. Dr. Ingeborg Reichle. This was followed by seven presentations by invited international experts on their research and their perspectives on the current state of bioluminescence research, moderated by Prof. Dr. Michael Mönninger.

Jaime Alonso Lobato Cardoso

Universidad Nacional Autónoma de México (UNAM)

and Prof. Dr. Román Alfonso Castillo Diaz

Universidad Nacional Autónoma de México (UNAM)

Prof. Dr. Pinar Yoldas

University of California San Diego

Malu Lücking

Biodesign, Budapest

with Juni Neyenhuys

mujō lab OHG

On behalf of Prof. Mette Ramsgaard Thomsen, Det Kongelige Danske Kunstakademi, the following took part:

Dr. Aurelie Mossé

L'École nationale supérieure des Arts Décoratifs (EnsAD)

and Daniel Suárez,

Humboldt University of Berlin

Claudio Flores and Danilo Flores

Founders of Mimotype Technologies GmbH, Berlin

Prof. DDr. Alberto T. Estévez

Universitat Internacional de Catalunya, iBAG (UIC)

Dr. Jae-Seong Yang

Universitat Autónoma de Barcelona, CRAG (UAB)

and

Dr. Yomna K. Abdallah

Universitat Internacional de Catalunya, iBAG (UlC)

Prof. Dr. Nico Dissmeyer

University of Osnabrück

Some of the research work presented is already on the threshold of application and incorporates the bioluminescent properties of different organisms as a possible source in the generation of light. Fungi, algae and bacteria played fundamental roles in the projects. One of the projects presented, for example, aims to create a multipurpose, multifunctional, and multiscale system to activate sustainability and beauty, which is to be used in art, architecture, and design in conjunction with bioluminescent genetically modified organisms. Another aim is to optimise the new light from bioluminescent sources and transfer it to architectural and artistic contexts in order to evaluate and further develop variables and results in the laboratory.

Many open research questions were addressed - and answered in different ways - for example, which organisms are promising for further research, how they can be further developed, how the lighting properties can be influenced and enhanced, or in which materials these organisms can be integrated. The integration of bioluminescent organisms into textiles was one of the approaches presented in order to preserve bioluminescent cultures in the long term and integrate them into architecture. The many visually appealing attempts at realisation that were presented provided an initial coherent picture of how this research could one day become visible and integrated into everyday life.

The first contribution was made by the Barcelona-based Genetic Architectures Research Group with the architect Alberto T. Estévez and the two scientists Jae-Seong Yang (computational and synthetic biology) and Yomna K. Abdallah (architect, computational designer, microbiologist). The second contribution came from biodesigner Malu Lücking and designer and illustrator Juni Neyenhuys. The following presentation was given by a Copenhagen-based working group led by architect Mette Ramsgaard Thomsen, who heads the Centre for IT and Architecture (CITA) at the Royal Danish Academy of Fine Arts. Aurélie Mosse presented the group's research approach. She teaches and researches design and is a co-leader of the Soft Matters research group of the EnsAD Lab, an internationally recognised French research laboratory for art and design at the Ecole Nationale Supérieure des Arts Décoratifs (EnsAD) in Paris. She was accompanied by Daniel Suárez, a Berlin-based architect who is involved in research into innovative materials, design interfaces and technological processes for architectural production in the context of the Humboldt-Universität zu Berlin's Cluster of Excellence Matters of Activity. The subsequent lecture was given by Claudio Flores, founder and CEO of the Berlin start-up company Mimotype Technologies. This was followed by a talk by Mexico City-based computer scientist and artist Jaime Alonso Lobato Cardoso from the Art, Science and Complexity Research Group of the Centre for Complexity Sciences at the Universidad Nacional Autónoma de México (UNAM) in tandem with molecular biologist Román Alfonso Castillo Díaz, who also works at the Institute of Molecular Biology and Biotechnology at UNAM. The San Diego-based artist and architect Pinar Yoldas then presented her project on speculative ecology and gave an insight into the BioArchitecture Lab she founded at the University of California San Diego. This was followed by the final contribution in the series by biochemist Nico Dissmeyer, who works at the University of Osnabrück, Department of Biology/Chemistry, Division of Plant Physiology & Protein Metabolism Laboratory.

The introductory lecture by Prof. Dr. Ingeborg Reichle at the beginning of the event, which brought together the various approaches, and the project presentations stimulated lively discussions between all participants. The detailed expert discussion led by Prof. Dr. Susanne Hauser and Prof. Dr. Ingeborg Reichle led to a highly professional, engaged and riveting exchange that identified key questions for future research. The opportunities for dialogue on the day were complemented by a variety of informal discussions, during which the invited experts networked with each other.

Due to the detailed project presentation of all participating researchers, the board of the Fritz and Trude Fortmann Foundation is now pleased to be able to support two of the projects over a period of two years with funding totalling EUR 150,000 each. The scientific work will be documented by the researchers and the results of their work will be published after completion so that they will be available to the international research community.

Workshop 2018

Spatial fabric - textiles and architecture

Textiles are among the oldest building materials known to mankind; they cover, create space, protect, separate, connect and decorate. Today, textile constructions and membranes offer new architectural design possibilities and functionalities; as material components, textiles open up promising fields of research and experimentation for the development of new building elements and construction methods. With its 2018 workshop ‘Raumstoff - Textiles and Architecture’, the Fritz and Trude Fortmann Foundation for Building Culture and Materials is exploring the significance of textiles for architecture and the future of construction.

Speakers and lecturers:

Prof. Dr. Regine Prange

Goethe University Frankfurt a.M.

Gottfried Semper's Carpet Wall. On the theory of the textile origin of architecture and its actualisations

Prof. Dr. Heidi Helmhold

Spatial Practices / University of Cologne

Textile Architecture - Affect Politics of Space and Body

Prof. Gabi Schillig

Düsseldorf University of Applied Sciences, Peter Behrens School of Arts

Responsive Architectures

Prof. Tobias Wallisser

ABK Stuttgart / LAVA (Laboratory for Visionary Architecture)

More with less - creating space with membranes

Dr. Peter Siemens

VERSEIDAG-INDUTEX GmbH, Krefeld

From fibre to architecture - development of high-tech textile building materials using the example of the Rottweil test tower

Workshop 2016

Building culture and materials

From left: Prof. Dr. Michael Mönniger, Prof. Dr. Joseph Schwartz, Prof. Dr. Jörn Düwel, Hannes Bäuerle, Martin Kaltwasser, Dr. Susanne Witzgall, Prof. Dr. Susanne Hauser

From left: Prof. Dr. Michael Mönniger, Prof. Dr. Joseph Schwartz, Prof. Dr. Jörn Düwel, Hannes Bäuerle, Martin Kaltwasser, Dr. Susanne Witzgall, Prof. Dr. Susanne HauserOn 3 March 2016, the Fritz and Trude Fortmann Foundation for Building Culture and Materials held its inaugural event in the Peter Behrens Hall at TU Berlin. The main topic of the event, which was declared a workshop, was the ‘Promotion of building culture and materials’, which was supported by prominent personalities from the field of construction through lectures and discussions. The workshop primarily served to provide impetus for the future work of the foundation, which was established in 2013.

The speakers were asked to address three key questions in their contribution:

- In your opinion, what are the most pressing issues relating to building culture and materials?

- What material-related issues are you currently working on or have you recently worked on? Are there any issues related to the topic that you would like to work on in the future?

- What significance could your questions have for current architecture and construction?

The following people contributed:

Prof. Dr. Joseph Schwartz

Structural engineer, Chair of Structural Design EHT Zurich

Prof. Dr. Jörn Düwel

Urban and architectural historian, Hafen City University HH

Dr. Susanne Witzgall

Cultural scientist, cultural historian, AdbK Munich

Martin Kaltwasser

Visual artist, architect, Berlin

Hannes Bäuerle

Material researcher, raumPROBE, Stuttgart

and the invited audience and the foundation itself.

An extremely multifaceted field has emerged, and the Fritz and Trude Fortmann Foundation has committed itself to bring it together. It became clear that the promotion of small, creative groups and a rethinking of the established forces in the context of building culture is necessary. That building culture and materials have an essential influence on human existence and that the need for a scientific approach is highly topical at this point. How do we want to live, what do we want to leave behind and, last but not least, what defines us as a global, modern society? These are profound and exciting questions that the Foundation has approached through its focus, and that affect us all. So there is still much to do. For, as inspiring and eventful as this day was, the certainty remains that Rome was not built in a day.

Critical Care. Architecture for a planet in crisis

An exhibition of the Architekturzentrum Wien, AZW

at the German Architecture Centre, DAZ, in Berlin

8 February - 22 March 2020

Anapuma Kundoo: Voluntary Home for Homeless Children, Pondicherry, India, 2010 \ © Image: Andres Herzog

Anapuma Kundoo: Voluntary Home for Homeless Children, Pondicherry, India, 2010 \ © Image: Andres HerzogThe presentation of the exhibition at the DAZ was supported by the Fritz and Trude Fortmann Foundation

Exhibition theme

Crisis and caring - these are the two poles of the exhibition title ‘Critical Care’. In English, the term ‘critical care’ also stands for intensive care unit. In any event, the exhibition conceived by the Architekturzentrum Wien fits in well with the BDA's annual theme of ‘Repair and Care’.

The earth in the emergency room. Man-made ecological and social disasters are threatening to make the planet uninhabitable. The situation is critical, and dominated by the interests of capital, architecture and urbanism are entangled in the crisis.

But there is another way, as the exhibition ‘Critical Care’ shows with 21 current international examples. These include: earthquake-proof and sustainable village development in China, flood protection using traditional low-CO2 construction techniques in Pakistan and Bangladesh, the diverse conversion of modernist buildings in Brazil and Europe, an ecological community land trust in Puerto Rico, the revitalisation of historic irrigation systems in Spain and new concepts for public spaces and mixed urban districts in Vienna, London and Nairobi.

The ‘Critical Care’ exhibition is a plea for a new mindset: for architecture and urbanism of caring. It proves that architecture can contribute to revitalising the planet. The repair of the future has begun.

Information

The exhibition of the Architekturzentrum Wien was curated by Angelika Fitz and Elke Krasny

Exhibition architecture: the next ENTERprise

Exhibition graphics: Alexander Schuh

Exhibition opening: 7 February 2020, 7 pm

The speakers were:

Angelika Fitz, Director of the Az W

Susanne Wartzeck, President of the BDA

Matthias Böttger, artistic director of the DAZ

Y-Table Talk: 24 February 2020, 7 pm

with curator Elke Krasny, Matthias Böttger and guests

Topics and participants:

Caring for water, land and soil:

URBANA / Kashef Mahboob Chowdhury

CICLICA and CAVAA

Fideicomiso de la Tierra del Caño Martín Peña CLT

Estudio Teddy Cruz + Fonna Forman

Colectivo 720

Caring for repair:

de vylder vinck taillieu

Paulo Mendes da Rocha and MMBB Architects

Lacaton & Vassal with Frédéric Druot and Christophe Hutin

ZUsammenKUNFT Berlin

Caring for skills and knowledge:

Rural Urban Framework

Yasmeen Lari / Heritage Foundation of Pakistan

EAHR, Emergency Architecture & Human Rights

Anupama Kundoo

Caring for public space:

muf architecture/art

City administration in Barcelona

StudioVlayStreeruwitz

Mixing: Nordbahnhof

Caring for production:

atelier d'architecture autogérée

Kounkuey Design Initiative

Anna Heringer

Xu Tiantian / DnA_Design and Architecture

Publication:

On the occasion of the exhibition, MIT Press published ‘Critical Care. Architecture and Urbanism for a Broken Planet’, edited by Angelika Fitz, Elke Krasny and the Architekturzentrum Wien. The book contains all 21 case studies as well as 12 essays by international authors on the topics of labour, economy and ecology in architecture.

Book presentation

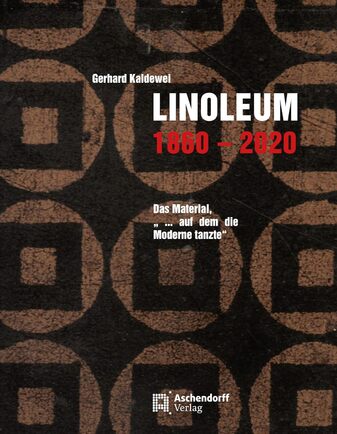

Linoleum 1860-2020: The material ‘... on which modernity danced’

Since the beginning of the 20th century, linoleum has been regarded as the material ‘on which modernity danced’. Between 1900 and 1930 in particular, it was used in architecture and design as a versatile, colourful or artistic floor covering. Many contemporary architects, designers and interior planners created new modern floral or graphic designs for linoleum: from Peter Behrens to Henry van de Velde, from Josef Hoffmann to Bruno Paul.

In the post-war period, the new ‘Inlaid “57”’ collection from Deutsche Linoleum-Werke introduced the floor covering of modernism in Germany at the pioneering Berlin building exhibition ‘Interbau 1957’. A total of up to 78 flats in the show houses - designed by the famous architects Alvar Aalto and Pierre Vago, among others - in the Hansa district of Berlin were predominantly furnished with the new and now contemporary linoleum. The architects Oscar Niemeyer and Le Corbusier also used linoleum almost exclusively as a floor covering in their large buildings in the Hansa neighbourhood. However, from the 1960s onwards, linoleum was increasingly seen as a material that was no longer in keeping with the times.

However, the growing awareness of sustainability gave the shrinking linoleum industry a major renaissance from the 1980s onwards. The demand for linoleum, which is made from natural and renewable raw materials, rose sharply again. Linoleum was rediscovered as an ecologically correct, climate-neutral and also colourful and interesting floor covering in architecture and design, as all the material components of linoleum are natural and almost completely biodegradable. Thanks to its recyclability, linoleum has a very good eco-balance and is also a resilient, elastic, modern floor covering which, if it were to come onto the market again today, would probably be one of the most important inventions of the century. This publication, sponsored by the Fortmann Foundation, takes a knowledgeable look at the fascination of linoleum as a material, as reflected in the history of literature in the 20th century.

The author Gerhard Kaldewei is a historian and was director of the Nordwestdeutsches Museum für IndustrieKultur in Delmenhorst from 1994 to 23011.

199 p., numerous illustrations, hardcover. Aschendorff-Verlag, Münster 2023. Euro 24,90

Linoleum 1860-2020. The material ‘... on which modernity danced’

Linoleum 1860-2020. The material ‘... on which modernity danced’